Plans are typically 90-95% complete when they are delivered to the Barton Malow team, which routinely uncovers areas for refinement on its jobsites. The ability to produce a correct 3D concrete model in the construction industry is a game changer – why?. At Leica Geosystems, you will find the professionals with whom to discuss your requirements and with the expertise to address them: specialists for aerial photography, experienced photogrammetrists, engineers, as well as service and maintenance specialists. The ADS40 is installed and tested by Leica Geosystems engineers.

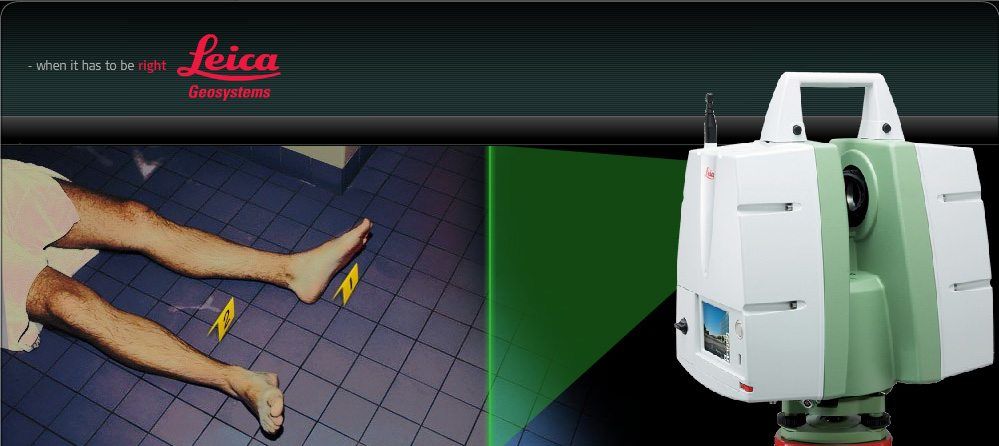

Utility Detection Solutions. Please read latest information update for customers in relation to the coronavirus outbreak. Hexagon’s COVID-19 Update. When it has to be right Leica Geosystems. Today announced that it will open a state-of-the-art laser scanner service center in May that will allow the company to service all current models of Leica ScanStation laser.

37 salaries for 29 jobs at Leica Geosystems in Atlanta, GA, US Area. Leica Geosystems Salaries trends. The new BLK3D is the industry’s first 3D handheld imager enabling.

Leica Geosystems Atlanta Manual Work To

Overall, it was a lot of manual work to get point data from the model and into a layout engineer’s hands, requiring too many manual modifications and exporting of point lists that required extra overhead.When Barton Malow talked with Leica Geosystems, they were the only provider that was easy to use and had the ability to integrate point to point. Instead, they had to pick points on a model and superimpose the image. Or, if they could do IFC, then just-in-time point extraction wasn’t possible. While our industry is making strides, we still face adoption constraints in the field coupled with a fairly manual process.”In talking with several companies, most were unable to export or convert IFC details into their software. “We need to balance that with field user and engineer comfort levels in using new technology tools and equipment.

Visual model views of plans for layout engineers allows them to see what’s underneath and after a specific pour, enabling foresight and insight into what’s next in the workflow.“With Leica, we’re able to rely on the model to plan and do the work,” added Trevor. While Leica provides a model to view, it’s also integrated into the workflow. Right away, you can see what comes after this step and pour.

They are able to find problems faster to course correct more quickly while saving money. In the as-build process with Leica, Trevor and team have access to information to inform decisions digitally to mitigate manual requirements. They save time on point picking workflows and have the extra information they need (vs having to request in advance). Using Leica, Trevor and team are able to eliminate the guesswork for all involved as everyone has access to data to make informed decisions.

“The guys would spend a good part of the day putting materials in the ground and the find out the footing wasn’t right so we wasted all that labor to get to that point. “It’s generally around this time when we’d find a mistake in excavation or some other problem,” says Craig Poortinga of Walrite LLC Colorado Foundation Contractors. Once this this process is completed, the layout begins. By adopting Leica iCON into direct concrete model layout workflows, Barton eliminates the point picking and sending the model to the iCON for just-in-time point extraction to deliver projects on-time, on-spec, and on-budget.Digital Layout Saves Concrete Contractor $2,000 Per WeekConcrete construction footing crews typically lay out footings with tape measures and strings. We’re able to identify any issues before the pour, saving time and money.”Looking to the future, every concrete job Barton Malow does – of any size – will have a construct able model in place to generate valid point data that’s been checked.

“Very rarely do I even find mistakes now. If you look at the mistake category before we began using the robotic total stations, 99 percent were layout errors,” he says. “Ninety-nine percent of the time, it’s a mistake drawn on the plans by an engineer. He notes that he still finds mistakes, but they are much easier to locate.

“There are no stings to run or extra stakes to drive to layout. “We build with no need to take apart because after layout, we see things that don’t fit,” Poortinga notes. I just make sure the machine isn’t going to tip over, so the wind doesn’t affect our work.”Robotic total station increases concrete work efficiencyUsing the robotic total station technology has made jobs much easier and more efficient because now the crew can just build and stake without the extra steps of a layout using multiple crew members. “With total robotic stations, you can keep going forward unless it’s pouring rain. “When you’re running a stringline 60- to 70-feet long with wind blowing 20 mph, you’re fighting the elements,” Poortinga says. However, when you’re running tape measures and strings, you make mistakes every day.”Using this technology has also enabled Walrite to work in some weather conditions that would have been very challenging with the traditional tape measure and stringline method.

It tells you where you have to go.”This translates to time saved on the jobsite. All you need to do is set up the machine and start walking around. Envision holding a stick with a computer on it and walking around until it says zero-zero, marking it as a point, and then putting a nail in the ground. “They can see which points they must build around.

Instead of having three guys together to do a layout, one guy can do that while the other guys focus on the other details of the job, such as putting foundations together and making sure we aren’t missing the drops.”Although the company has not yet been involved on any projects with a BIM requirement, Poortinga sees the value of moving to a BIM workflow. “I’m not only saving on those parts of the job they don’t need to do anymore, but I can have them focus on other parts of the job that make it better. This adds up to a $1,500 to $2,000 savings per week.“It’s a daily savings for me,” Poortinga says. The company is now on the profit margin side, saving about $300 to $400 per job in time, with an average of about a job per day. “Now add to that the ease of work and not having to tear apart and fix things, and we see a substantial savings,” Poortinga says.Poortinga says Walrite was able to achieve its return on investment within two months of using the robotic total station. For custom homes, a total of six man hours are saved with three crew members at an hour each.

“If I can beat it, I can be better in my business by taking that weakness and trying to overcome it,” Poortinga says. Instead of taking days, a really complicated house can be laid out in two or three hours.”Poortinga says if he sees a deficiency in his business or if there is something in which he is not confident, he wants to change it. This machine takes the fear out of some of these custom homes. They are changing angles and bringing details into a house. People are looking for more in a home than it just being a square box. Houses are becoming more complicated.

0 kommentar(er)

0 kommentar(er)